Clay is not the first material that comes to mind when thinking of a next-generation biomaterial for tissue engineering. However, researchers at the University of Southampton and the Technische Universitat Dresden have used Laponite, a synthetic nanosilicate clay, to 3D print human mesenchymal stem cells (Biofabrication 9 034103).

The team developed a new bioink, a material that contains cells, by combining Laponite with alginate and methylcellulose. The Laponite improved the printability of the bioink due to the shear thinning properties of the clay, whilst allowing high cell viability and maintaining scaffold shape for up to 21 days. Furthermore, Laponite has potential as a drug delivery agent, demonstrating sustained release of two model proteins included in the bioink.

“The inclusion of Laponite into bioinks enables development of new compositions due to the interesting interaction capability of Laponite with polymeric hydrogels,” explained corresponding author Richard Oreffo from the University of Southampton.

Improved printability

A major issue in 3D bioprinting is the ability to print materials that maintain their shape after deposition, whilst still enabling appropriate cell survival and maintenance of functionality. Bioink properties such as viscosity and the gelation process can be tuned to improve the printing process and final structure.

In this work, the researchers used Laponite, which is employed in the cosmetics industry as a thickener or filler, to improve the properties of their bioink. The clay consists of disc-shaped particles, 25 nm in diameter and 1 nm thick, which can self-assemble into a gel due to electrostatic interactions between the clay nanoparticles’ negatively charged face and positively charged rim.

One of the key advantages of Laponite is the shear thinning properties that it imparts. Shear thinning is the ability of a material to temporarily decrease its viscosity when a stress is applied. Tomato ketchup, for example, exhibits shear thinning and only flows or squirts when a force is applied. By including Laponite, a higher viscosity bioink can be used that maintains its shape after being extruded.

Bioprinting scaffolds

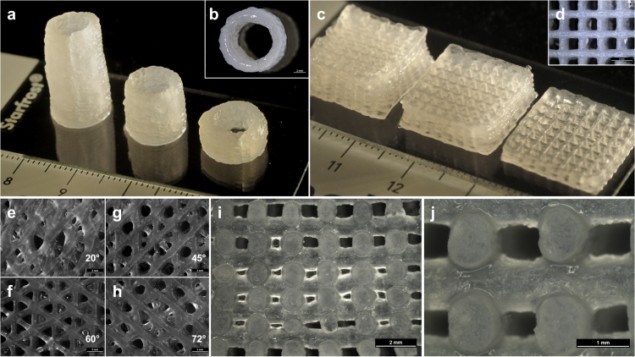

The researchers created scaffolds (the structures that provide support for cell growth) using an extrusion-based process, 3D plotting, which allows printing at low temperatures and physiological conditions. They prepared a variety of bioink blends to determine the optimal composition for printability and promoting shape fidelity of the scaffold. A 3-3-3% blend of Laponite, alginate and methylcellulose was determined to be optimal for extrusion and scaffold shape.

After extrusion, they incubated the scaffolds with calcium chloride to allow crosslinking (gelling) of the alginate, which partially solidifies the scaffold. The scaffolds maintained their shape even after 21 days of incubation in cell culture conditions, although the mechanical properties altered, transitioning from flexible and tough to soft.

The researchers encapsulated immortalized mesenchymal stem cells within the bioink and showed that the printing process and inclusion of Laponite allowed high cell viability, 70–75%, even after 21 days of culture. Laponite actually had a positive impact on cell viability, with the bioinks without Laponite exhibiting reduced cell viability. The authors are currently working towards the inclusion of Laponite as a hydrogel system in combination with biomaterials that currently have limited printability, shape stability, and biocompatibility.

Drug delivery

Finally, the researchers demonstrated the use of Laponite as a drug delivery agent that allows the sustained release of two model proteins, bovine serum albumin (BSA) and vascular endothelial growth factor (VEGF), included in the bioink. They compared the release profile of these proteins in scaffold with and without Laponite.

Whilst non-Laponite scaffolds displayed a high initial burst of protein release, the Laponite-based scaffolds showed a sustained release profile. The authors suggest that Laponite provides electrostatic interactions that can bind proteins. This ability opens the door for long-term release of drugs and proteins that can promote specific cell behaviour and could be an important step in the field of bioprinting.

“The bioink consisting of Laponite, alginate and methylcellulose showed advanced printing properties and a positive cell survival rate,” said Oreffo. “Our next steps will focus on enhancing the cellular response within these printed constructs, either by subsequent preservation of the crosslinked state of the scaffolds or by usage of the attractive growth factor binding capabilities of the bioink with proteins that enhance cell responses.”